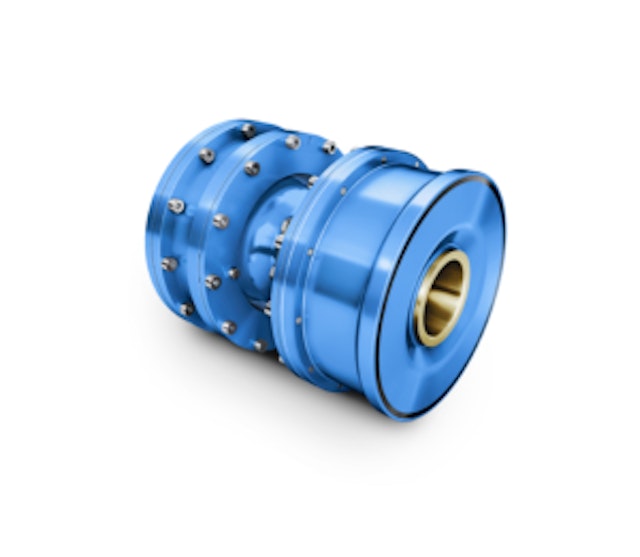

ZBG Gear Coupling

The torsionally rigid ZBG curved-tooth gear coupling from FLENDER offers your application the assurance of maximum availability in its field of application. No matter on which route, with the strongest starting torques and speeds, extremely dusty conditions, axial or radial shocks at top speeds, the ZBG coupling from FLENDER always offers you the highest level of quality.

The ZBG coupling system is of robust and weight-optimized design and all heavy components are mounted directly on the engine and the transmission shaft. All internal components compensate for operational misalignments so that only minimal imbalance forces and vibrations are generated.

A potential fire hazard due to lubricant leakage is eliminated with the ZBG coupling by closed fixed chambers.

Features

Long service life with low maintenance requirements

First maintenance work only after > 3 million running kilometers or 12 years

Low-wear and service-friendly design

General inspection together with gearbox and engine

On request, the delivery can be made with grease filling and ready for installation

Simple and very fast relubrication via grease nipples

Excellent emergency running properties due to closed grease chambers

Significant load-bearing reserves even after very long running time

Optimized sealing system against dust penetration

Safe running in icy conditions and at high temperatures below freezing

Heat resistant even under extreme loads

Fields of application

industry

a.o.: metros, high-speed trains

Torque range

up to 3.000 Nm

Temperature range

–50 °C to +55 °C