Good to know.

REICH Rubber couplings – Highly flexible precision for modern drives

Rubber couplings from REICH are among the indispensable connecting elements in common power transmission systems. When it comes to operating drive systems smoothly and efficiently, the manufacturer from Bochum is a safe choice. The clutch manufacturer REICH sets standards in drive technology with innovative solutions such as the ARCUSAFLEX® and the MULTI MONT SELLA. This article will explain what makes these products so special and why they are the first choice for many applications.

Factors that influence the service life of rubber couplings

Rubber couplings have become indispensable elements in power transmission in industry. The components ensure smooth, low-vibration and shock-absorbing transmission of torques to machines. Modern rubber couplings are robust and low-maintenance. However, their service life depends on various factors. This article explains what these are and how the service life of rubber couplings can be influenced or extended.

Documentation is always a task that many companies and employees like to put on the back burner or forget about. However, complete documentation is essential for the operation of machines, gearboxes, drives, couplings and engine mounts. Missing documentation data leads to lengthy processes, errors and wasted time. With PMP+, PMP Service GmbH offers a solution that structures, secures and makes retrieval of important documents available at any time.

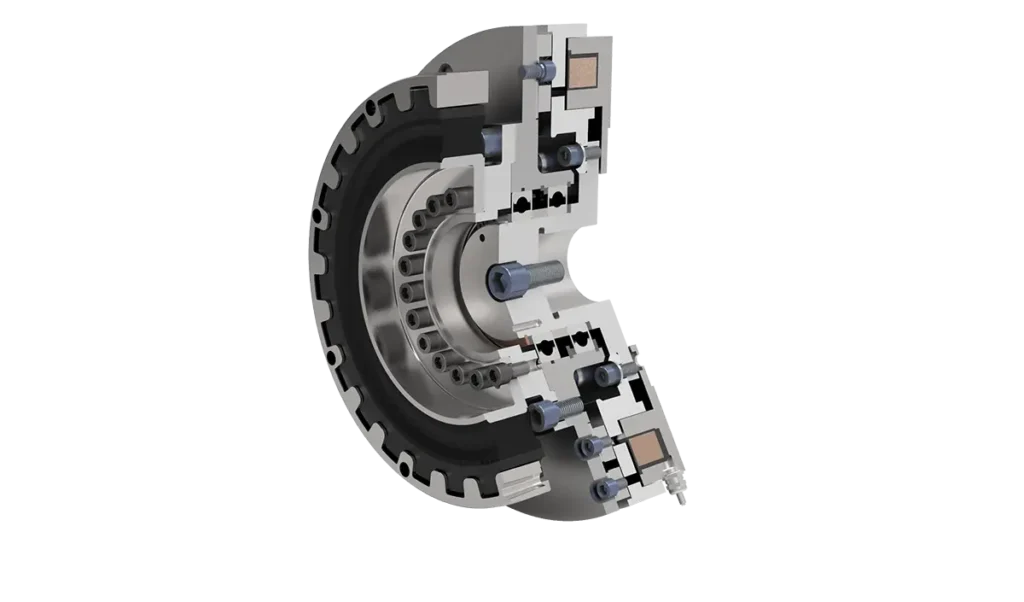

Stromag 2in1 clutches stand for advanced technology and maximum efficiency in power transmission. By combining Coupling and brake functions in a single compact unit, they offer a unique solution for numerous industrial applications. As an authorized specialist dealer, PMP Germany is your reliable partner when it comes to the selection, integration and maintenance of these innovative Couplings. In this article, you will learn everything you need to know about the benefits, areas of application and technical details of Stromag 2in1 clutches.

Stromag Couplings – Versatile solutions for every requirement

For decades, Stromag Couplings have stood for outstanding quality and reliability in power transmission technology. Whether in marine, agricultural or industrial applications - Stromag offers customized solutions that meet the highest demands. As an authorized specialist dealer for Stromag couplings, PMP Germany GmbH supports you in finding the right coupling for your specific requirements. In this blog post, you can find out more about the different types of Stromag couplings, their areas of application and the many benefits that these first-class couplings offer

Vulkan Couplings

Welcome to our comprehensive knowledge article on Vulkan Couplings, presented by PMP Germany, your expert for drive technology and coupling systems. In this section, we delve into the fascinating world of Vulkan Couplings to provide a deep understanding of these key components in various industrial sectors.

Common errors when aligning Couplings and how to rectify them

The correct alignment of Couplings is a critical aspect of the performance and longevity of machinery and equipment in numerous industries. From marine and agricultural to industrial and energy, the impact of misaligned couplings can be far-reaching, from loss of efficiency to increased maintenance costs and downtime.

Methods for aligning Couplings

In the field of mechanics and mechanical engineering, the correct alignment of Couplings is a decisive factor for the performance and service life of machines. Coupling alignment is a technical process that aims to position two or more shafts in such a way that they ensure optimum power transmission while avoiding unnecessary wear.

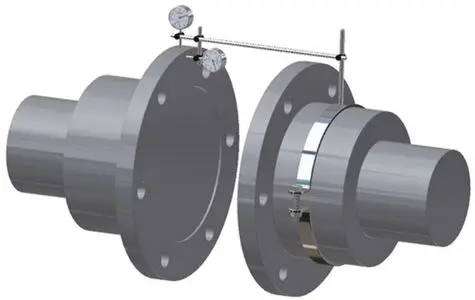

Basics of alignment control for Couplings

Importance of alignment control in various industries Coupling alignment control is a critical process that is essential in many industries. Precise alignment ensures efficient power transmission, minimizes machine vibration and prevents premature wear.

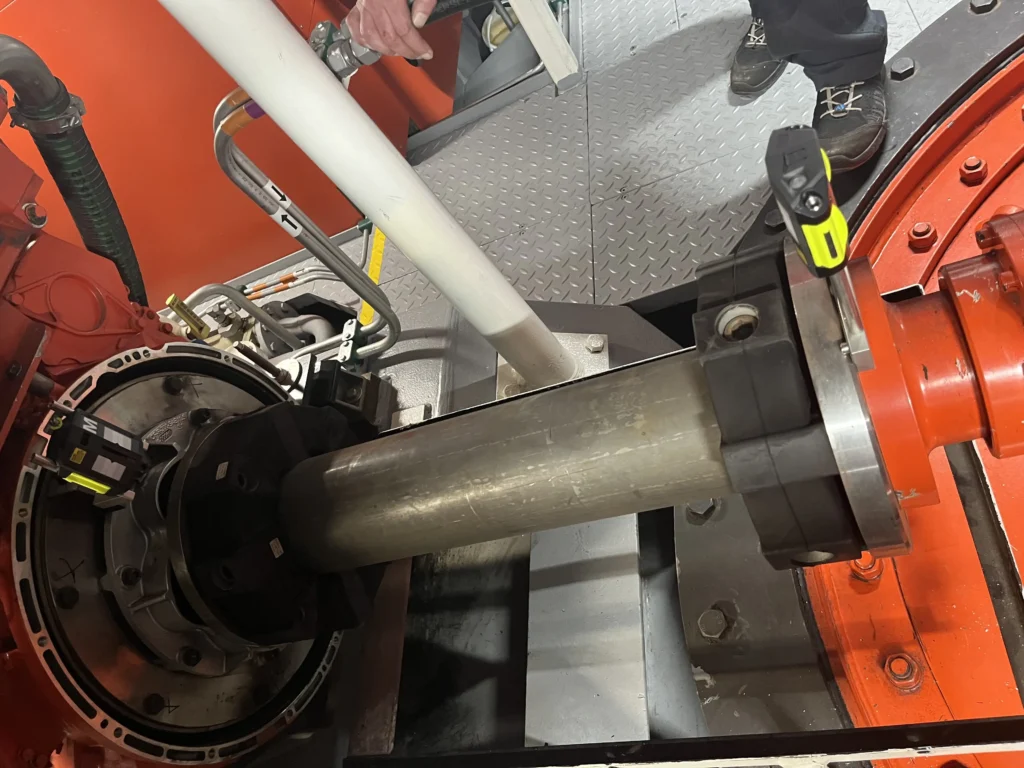

Maintenance and servicing of Vulkan Couplings

Welcome to our in-depth blog post dedicated entirely to the maintenance and servicing of Vulkan Couplings. Vulkan Couplings are known for their robustness and reliability in demanding industrial applications. However, like any high performance system, they require regular maintenance to maintain their functionality and efficiency. In this first section, we highlight the importance of this regular maintenance and provide an overview of the main maintenance activities.

Wave alignment with the laser

Shaft alignment is essential to ensure that the drivetrain functions optimally. Perfect shaft alignment is essential to avoid expensive repairs or even breakdowns. In this article, we at PMP explain the advantages of shaft alignment with a laser and present our services in the field of alignment control.

Highly flexible Couplings

Couplings play a central role in the field of drive technology. They ensure the smooth transmission of torque and make it possible to synchronize movements between different components. In this article, we will take a closer look at highly flexible couplings.

Thrust bearing

Together with the technical joint, bearings are among the guiding elements in machine and device construction. The bearings enable movements in desired degrees of freedom. They also restrict movement in undesirable degrees of freedom. A distinction is made between different bearing types according to these degrees of freedom.

Rigid Couplings

Couplings connect two shafts together. Depending on the design of the machine, this connection can be rigid, flexible or even flexible, making it necessary to install a flexible or rigid Coupling. In the past, rigid couplings were regarded as the inexpensive, imprecise variants of couplings.

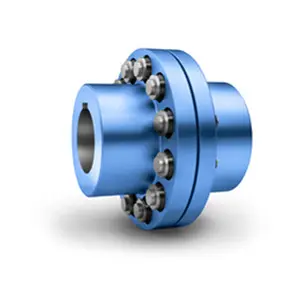

Pin couplings

Pin couplings consist of two flanges that are joined together. On one flange, bolts are evenly distributed in a circle. The second flange has matching recesses into which the bolts engage.

Movable Couplings

Whether rigid, flexible or flexible couplings: It should be noted that shaft couplings are indispensable elements of any drive technology and create an effective connection between two shafts. The main task here is the reliable transmission of torque.

CENTA drives

When it comes to Couplings, CENTA Antriebe Kirschey GmbH is an absolute specialist. CENTA's global portfolio includes both torsionally flexible and torsionally rigid couplings. Each individual Coupling is responsible for transmitting the power of the engine to the transmission.

REICH Couplings

The manufacturer REICH describes REICH Couplings as a symbol of "smooth and efficient economy". Based in Bochum, Germany, the company REICH offers an extensive portfolio. This portfolio divides couplings according to their elastic behavior - highly torsionally flexible, torsionally flexible and torsionally rigid.

Flexible claw coupling

The flexible claw coupling - also known as a torsionally flexible coupling, elastomer coupling, cam coupling or shaft balancer coupling - consists of two coupling halves (hubs) and an elastomer ring gear. In addition, there are concave claws (cast cams) on the end faces of the hubs, which engage with each other. The elastic spider fills the remaining gaps and consequently gives the Coupling its damping properties

FLENDER COUPLINGS

FLENDER GmbH is an international manufacturer of mechanical and electrical drive systems that has been offering a wide range of gear units, Couplings, generators and associated services for more than 120 years. Customers can purchase both universal and customized gearboxes, Couplings, etc. Requirements are adapted to the specific application and implemented according to the customer's wishes.

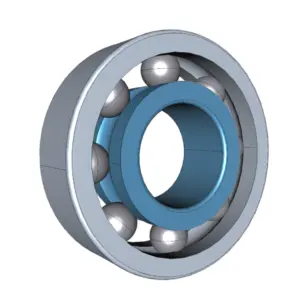

BALL BEARING MANUFACTURER

In this blog post, you will learn about two quality features that make your ball bearing run smoothly and that we pay attention to when purchasing ball bearings from different ball bearing manufacturers.when comparing rolling bearings or ball bearings from different manufacturers, there are considerable differences in quality. Rolling bearings are functionally critical machine elements. We therefore always select products from different ball bearing manufacturers with care.

Special clutches from PMP Individual

The prefix "special" in the word special couplings already expresses that something is not "commonplace", but is intended for a special purpose. And that is exactly what PMP Individual's industrial clutches are. In view of the infinite possibilities of power transmission between engine and gearbox, it is somehow almost completely normal that every application needs its own special clutch solution.

Tools on site

Is your Coupling defective and needs to be repaired? It is always advisable to have the right tools on site to repair your Coupling. Depending on the working environment or workplace, different tools are required on site. But no matter what area you work in: high-quality tools are an absolute must! After all, removing annoying rust film or the annoyance of a tool that cannot be used is nerve-wracking. What's more, a non-functioning Coupling is fraught with costly downtime. Take precautions.

Care of rubber couplings

The care of rubber couplings - we tell you what you need to consider. Rubber elements are used both for power transmission and for damping vibrations. In addition, rubber elements (depending on the Coupling) compensate for radial misalignments, angular misalignments and axial misalignments. In addition to choosing the right rubber element, you should also pay attention to regular care and maintenance of the elements.

Shaft alignment

Rotating machines are particularly susceptible to misalignment. And this can have fatal consequences. Find out more about our important alignment check service (shaft alignment). How do we carry out shaft alignment? What are the benefits of shaft alignment? You can also read about the consequences of incorrect alignment for you and your company.

How long does a Coupling last?

How long does a Coupling actually last? And what influences the service life of the Coupling? We will now explore these questions in this article. As an elementary part of the drive, the Coupling is subject to particularly high loads. But how long does a clutch actually last? And how can you extend the service life of a machine's Coupling?

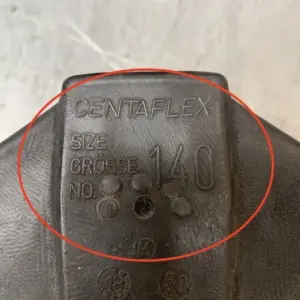

Identifying the Coupling – finding the right spare part

Coupling is a detachable connection between the engine and transmission. Machines can only be set in motion through the frictional connection.

When should you have your Coupling serviced?

Coupling maintenance - definitely important, but why exactly? Couplings are connections between the drive unit (e.g. engine) and the output unit (e.g. gearbox). Couplings are used in various areas. These include the marine, industrial, agricultural and energy sectors.

Rubber elements for Couplings

One or more rubber elements are installed in some Couplings. These elements perform important tasks within these couplings. The valuable contribution of rubber elements should therefore not be underestimated. After all, effective and efficiently functioning couplings minimize the risk of failure in your machines. is your coupling compatible with rubber elements?

Shaft couplings: Types, design and features

In this article, you will learn more about the types, design and features of shaft couplings. You will also be given tips on what you should look out for when selecting a shaft coupling.

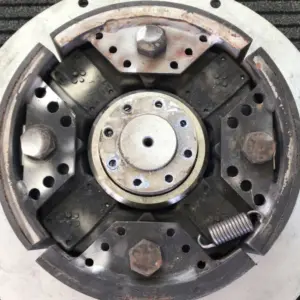

Centrifugal clutch: design and advantages

Centrifugal clutches have a very special feature: they are independent! No external power supply is required for operation.

Flexible Coupling as an essential element

In this article, you will learn more about the flexible coupling and the special forms of flexible couplings. It also describes the importance of application-specific coupling systems.

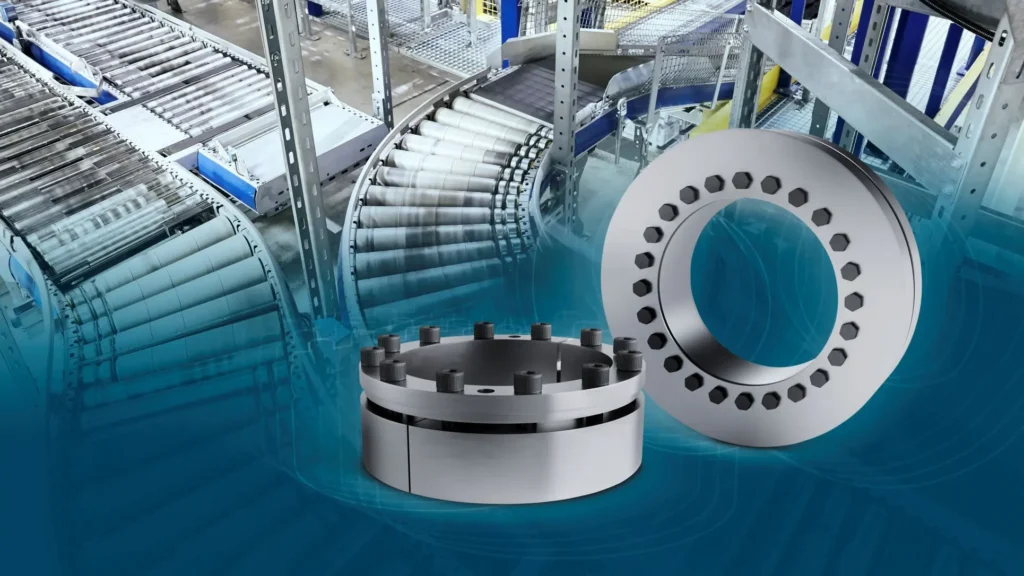

Clamping elements for shaft-hub connections

Shaft-hub connections are essential in industry. There are many variants for efficient torque transmission, including frictional connections. Flender's Fastex series offers compact, backlash-free clamping elements. At PMP we explain their advantages and describe various designs and applications.